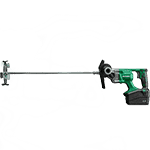

Power Tool

Maintenance Schedule.

Like all precision machinery, HiKOKI Power Tools require regular ongoing maintenance in order to remain in top condition,

and keep them protected from the harshness of modern workshops, construction sites and outdoor environments.

Your local HiKOKI Service Agent can discuss with you a maintenance plan suited to your particular environment,

application, and frequency of work but essentially your power tool should be inspected for carbon brush wear (if applicable),

bearing and seal wear, gearbox grease changes, contamination by dust, grit, water, or solvents, as well as electrical mechanical

safety checks. Like any machinery, regular attention to maintenance issues goes a long way towards preventing

major component failures and frustrating down time on site.

Select your product category below to see HiKOKI's recommended Service Intervals and maintenance requirements

#Refer to the instruction manual for Safety Checks. Tools should also be regularly checked for safety compliance in accordance with AS/NZ 3760

*Actual frequency varies according to workflow and environment

Click Here to book a Tool Service

Click Here to find your closest Service Agent